|

|

|

#1 |

|

GAS POWERED SHOTGUNs comparison - gas shell eject/gas shell/gas

Since I started collect shotguns for three years, I did all the fix and modify by myself, and I've been owning Hwashan, Maruzen, Marushin, APS and Marui, but not Tanaka(discontinued). Luckily I had a chance to modify a legend piece, the "Tanaka M870" to fulfill my airsoft Shotguns desire! Here is something I would like to share what I'd learned from them. That may take a bit long time to complete this post. Please be patient if you are interested in reading this. If you have any idea would like to share, please feel free to do so, thanks.

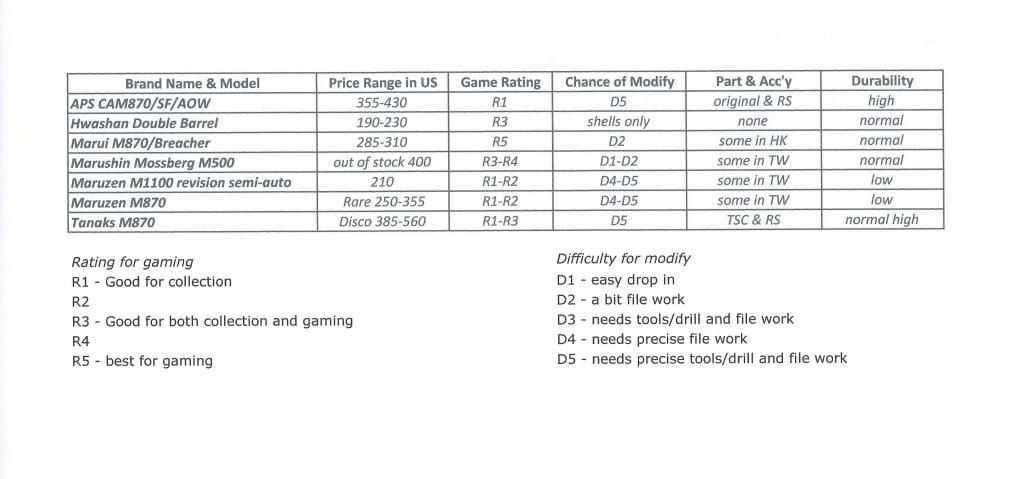

the following details on each items will be parts listing with pictures, modify and functional test with video if any. Reference Chart: Difficulty for modify D1 - easy drop in D2 - a bit file work D3 - needs tools/drill and file work D4 - needs precise file work D5 - needs precise tools/drill and file work Rating for gaming R1 - Good for collection R2 R3 - Good for both collection and gaming R4 R5 - best for gaming Gas Shotgun Showcase: Tanaka M870 Marushin Mossberg Maruzen M870 Marui M870 APS CAM870 pistol grip Maruzen M1100 revision Hwashan Double Barrel  Remington M870

__________________

aka Uncle

Last edited by N_Force; September 15th, 2014 at 19:11.. |

|

|

|

|

|

|

#2 |

|

Tanaka M870 - green gas Tanaka shell ejected/CO2 & green gas Madbull shell ejected

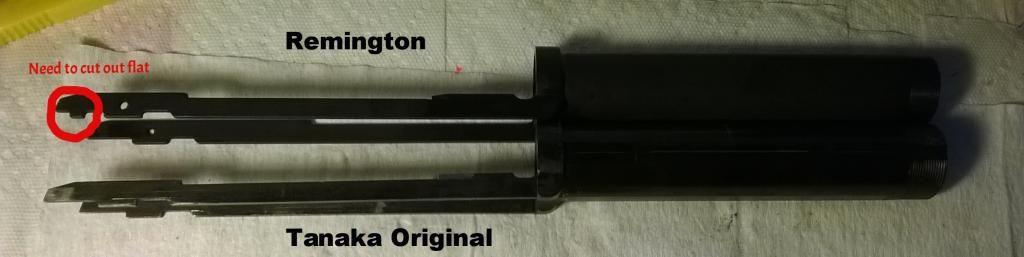

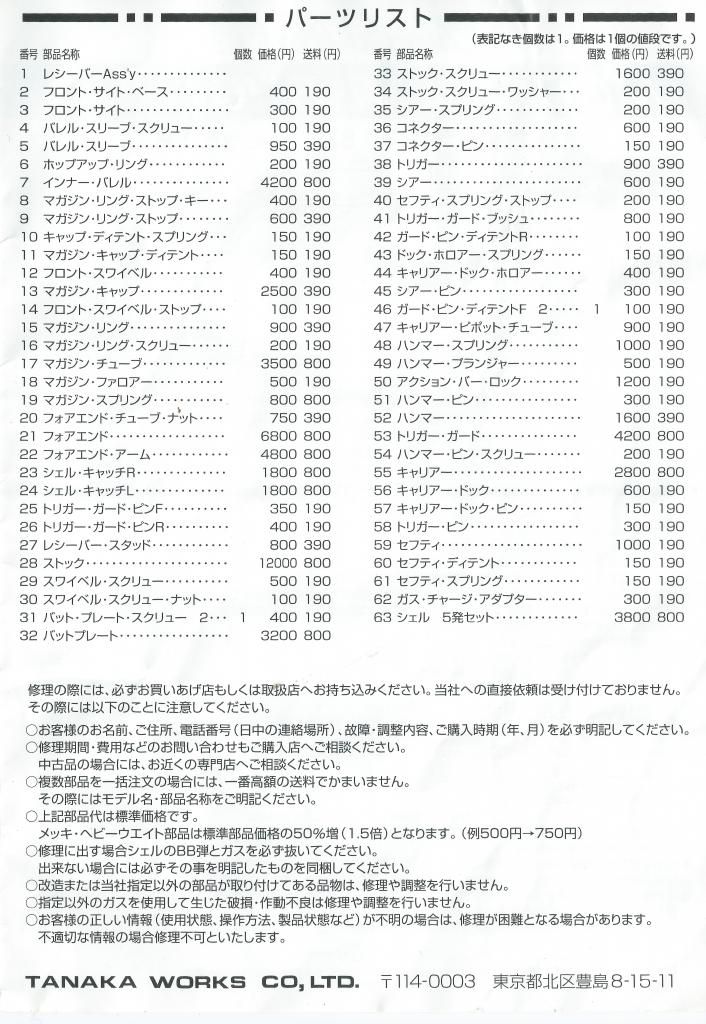

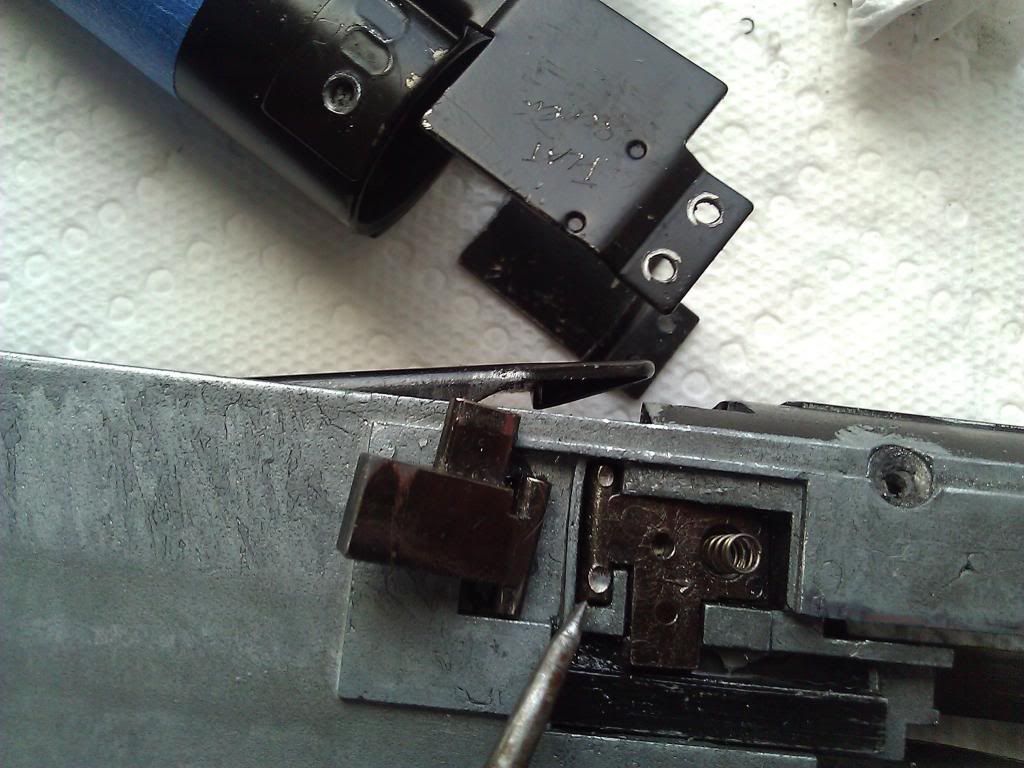

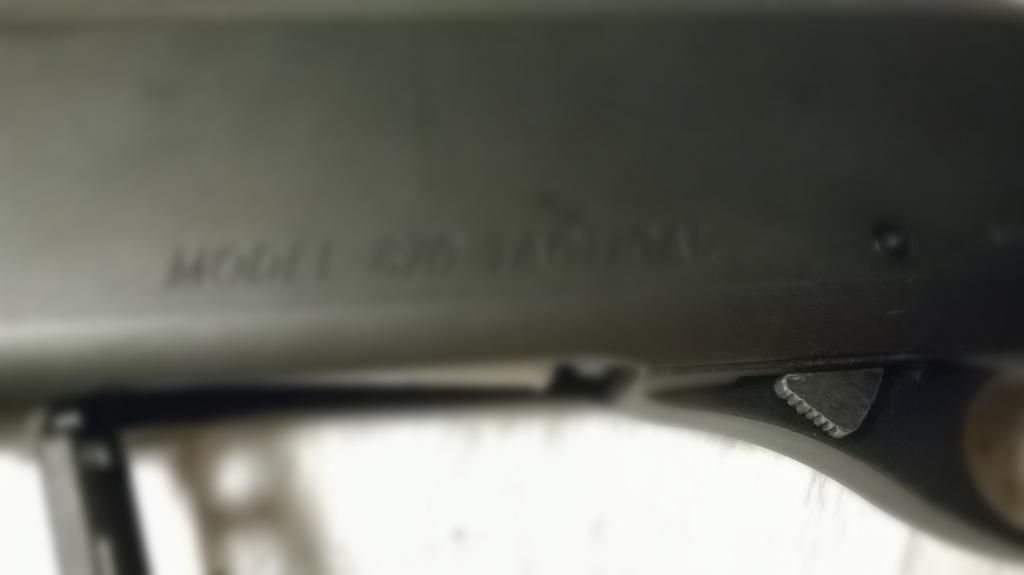

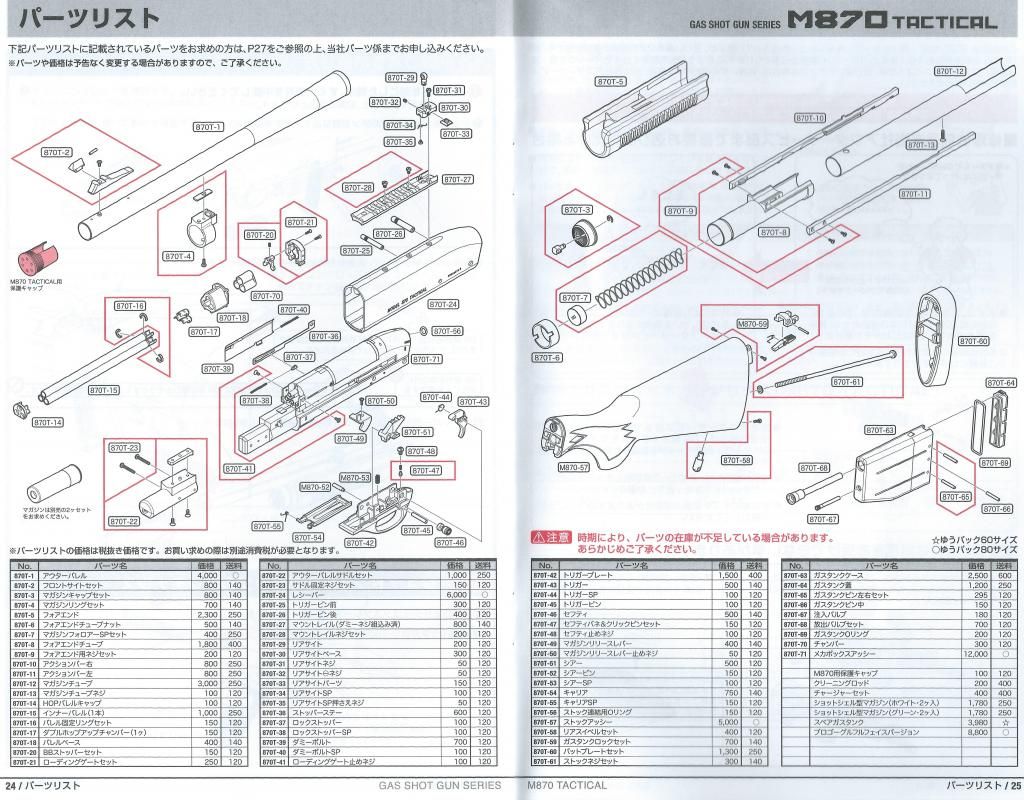

Completed on Jan1-2015 Was the most realistic shotgun in the market based on the bolt design and the "kicking" sound. Also after market upgrade parts, even the RS parts compatible, can bring it back alive almost 95% functional and working condition, believe it or not. A truly the best collector piece after all! Years ago, someone did this modify and posted it in public site. I read it after I completed my project, and felt like we did it almost the same idea. But that person didn't post how the functional worked. That's the most important part of modify. Whatever we use the parts no matter the after market and the RS parts, all need to be done is making it more durable and perform the best. And that's the reasons why I post this out to share. Design Single inner barrel with fixed hop up, gas and bbs are loaded in shell, mostly metal finishing, pretty realistic bolt design like RS. Chance of ModifyD5 There are bolt set and hammer group made by TSC, and also you can use Remington RS parts like loading arms, latches, carrying dog, extractor and parts, the stock and front grip. I believe the shell carrier could be modified in it too. It's a lot of chances can keep it the best perform. But the only part is the barrel. you need to drill it out and keep it in good shape and thread two holes to secure it back in receiver. If you break it, I've found a difficult way to fix it. Not a problem at all. Durability Pot metal & plastic are the original, and TSC reinforced material & Remington RS are the after market materials. So it's all good to last. Maintenance Regular lube and clean up is needed Parts Support Have TSC and Remington RS parts RatingR1-R3 since it is use shells, for practical shooting and collector piece would be good, for CQB would be fine, for long game then you need to have enough shells and spend time to reload. Custom made part: -Ejector Spring ~ D5  After market upgrade parts list: -T.S.C. Reinforced Breech Bolt Assembly for Tanaka M870 (Steel) ~ D4 -T.S.C. CNC Reinforced Steel Slide for Tanaka M870 Shotgun ~ D2 -T.S.C. CNC Reinforced Steel Hammer/Sear/Connector for Tanaka M870 ~ D4 Reinforced Breech Bolt Assembly & CNC Reinforced Steel Slide ~ D4/D2  Sear ~ D4   Hammer ~ D4  Remington parts list: -Remington Forend Tube Assembly -Remington Fore End Tube Nut 870 12 Gauge -Remington Shell Latch LEFT/Right 870 12 Gauge -Remington Carrier Dog ~ D1 -Remington Extractor/Plunger/Spring ~ D2/D3 Forend Tube Assembly - Top - Remington, Bottom - Tanaka Original  Shell Latch LEFT/Right - both middle one are Remington parts and need to be cut open at the end for lock in place  Carrier Dog ~ D1  Extractor ~ D2  test firing with Tanaka shells http://vid1285.photobucket.com/album...psd2c067e5.mp4 test firing with Madbull shells http://vid1285.photobucket.com/album...ps6362f3f1.mp4   Diagram

__________________

aka Uncle

Last edited by N_Force; January 1st, 2015 at 14:56.. Reason: added infos |

|

|

|

|

|

|

#3 |

|

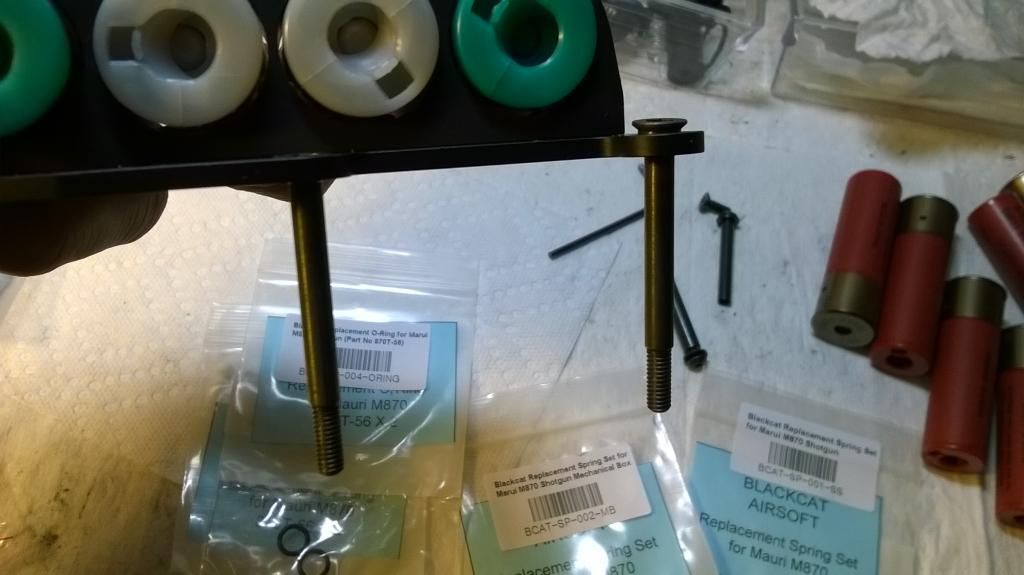

Aps cam870 - CO2 gas shell ejected

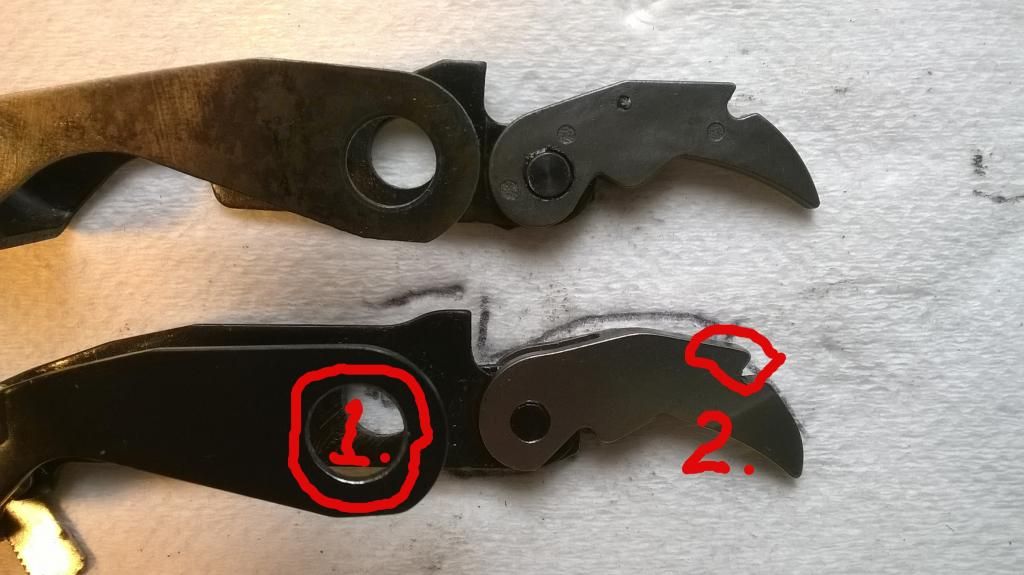

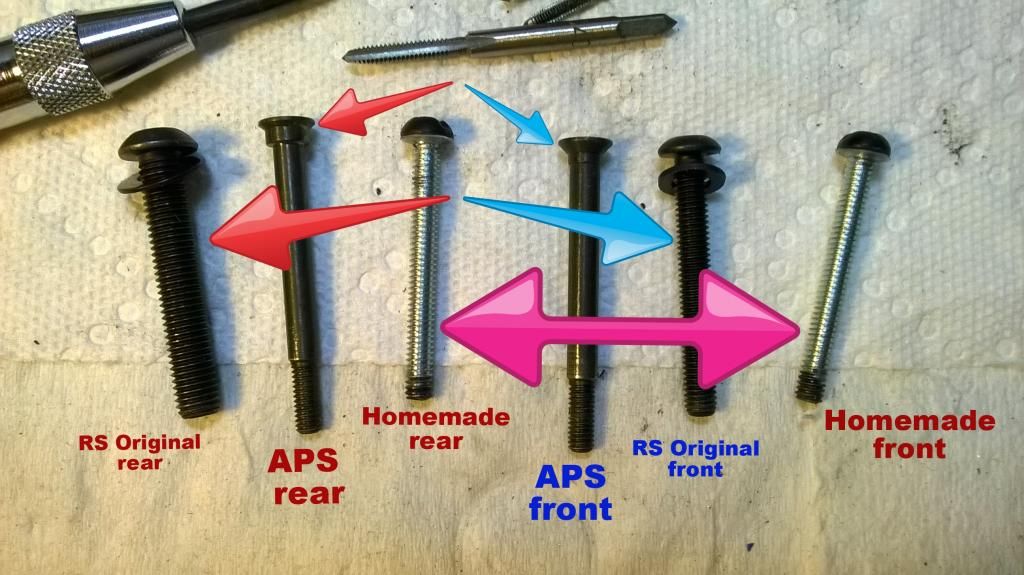

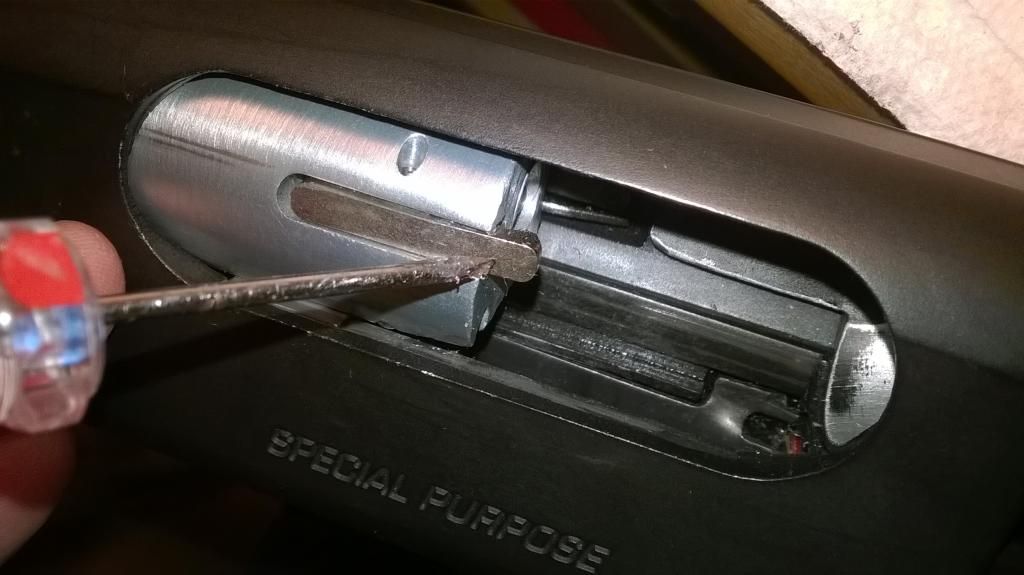

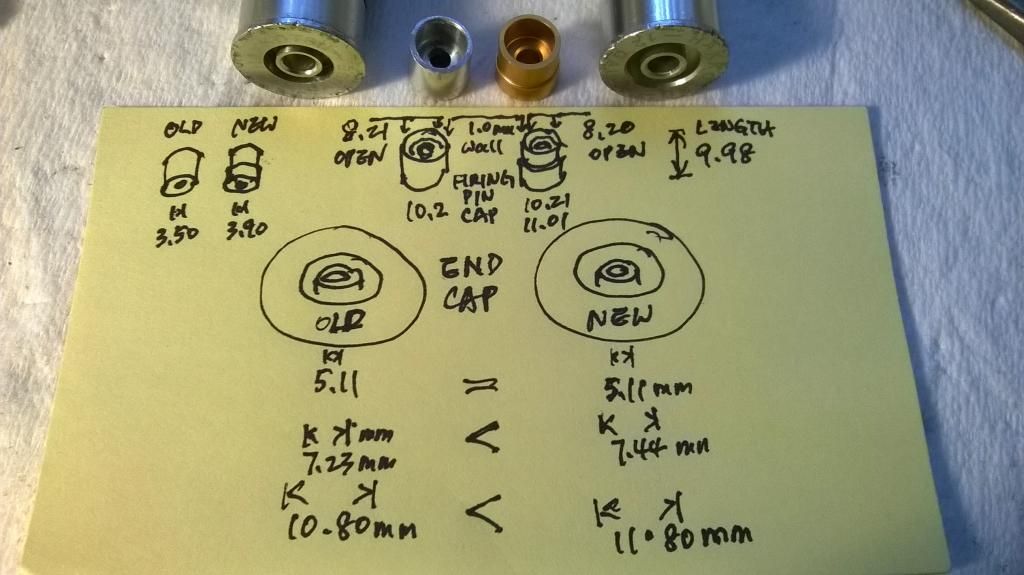

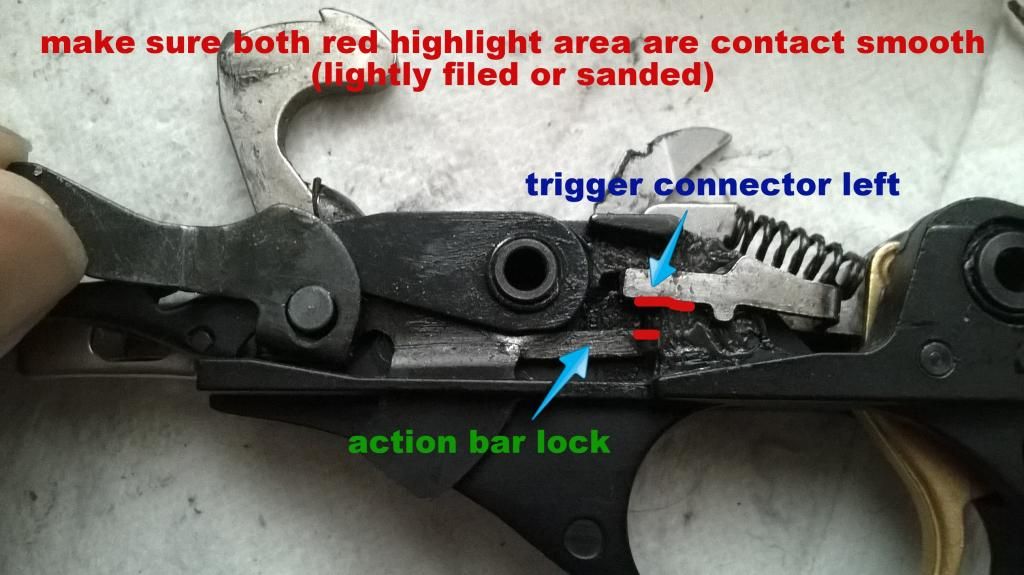

Completed on Jan1-2015 More info's will be followed if any New Video Added on Nov16/2014 http://youtu.be/jfI5wXu3Kjw  This bad boy has exactly the way to be disassembly like RS, even the stock and forend, sling attachment, you can get RS or airsoft both works great. But the side saddle, have to get the one that fit for same size of two receiver pins, or you have to modify the RS one, (see below for modify) not like RS has two receiver pin sizes. Design No inner barrel at all out of all those other shotgun pieces, very close to the RS. This is powered by CO2, gas and bbs are both store in shell. That makes the internal design is almost as same as RS. Of cause, the shell eject is function like RS too. Because the bolt design only come in one solid piece, so when racking it, doesn't have the nice clicking sound. Bolt in one piece  Chance of modifyD5 Since the internal parts are pretty close to RS, I did change the trigger to RS one in gold color, also the loading arm to competition one. They need to have precise modify to make it works. The rest of the trigger parts should work the same. The front tube can also use RS, grip and forend too. The parts may not be used is the two latches, must be original one. All the replacement parts are available in APS website. The bolt is port metal and no way to be fixed or modify. It's permanent lock threaded. I broke the firing pin and has to get back to APS order a replace one. RS Gold Trigger  RS shell lifter top-original, bottom-RS Enlarge the hole for pin insert - 1. Shorten the dog carrier to meet the size as original - 2   Original trigger group  Rem870 Side Saddle Since this APS shotgun has two same size of receiver pins, so when you need to add a side saddle on it, you need to modify it or get the APS scope mount pins to fit it in. Also you may need to tap a thread for screw.  I use two metal screws same size as APS one, cut in same length and metal blue it for support  Different between all three set of screws  Drill two holes beside original thread, tap a thread as same size as metal screws, it's done  If you want to try the APS scope mount pins, you may have to disassemble the side saddle and tap the right size to let the screw sit in properly, then assemble back  This is the one for Marui M870 and using APS scope mount pins to install.  Marui side saddle with its own screws set  APS CAM870 - Tune-up guide Shell Jam This is the most common angle for shell jam or struck  **Extra info's for fixing shell jam** the reasons for shell jam is causing by 1, the condition of front contact of the bolt (the most important), the top green circle, make sure it files & sand around that area a bit round and smooth to let the end cap of the shell slides through that area easily. You may take it out and use a shell, angle it as the same as jam and test slide contacting on it and see how is the fiction. If you feel rough and not smooth, that's the problem.  2, is it smooth on the surface of the end cap of the shell (also important) Mine are damaged a bit so this rough area will create fiction and increase the chance of jam, so I did sand it smooth to make it works the best and minimize jamming.  these are not the worst I have, some of them are even much worse than that! 3, the opening of the chamber when shell loading (not important but this will help for wider angle loading up) use file to file the lower part of the chamber to give wider angle. I would suggest using sand paper first, if not working better then use round file.  4, the last, may not necessary! is the front edge of shells. Sometimes I've found that is a bit sharp edge and I just fine sand a bit to help a better angle to be loading in chamber. When first I had my CAM870, I had jam once every 6-10 shots. I marked down the shells got jam and did this process. Also compare the overall length of the shell see if anyone of them are longer. That could be the shell front piece not screw tie enough to the end piece, so when the shell is longer, that needs to have a wider angle to load into chamber and causing jam. **End of the extra info's for fixing shell jam** APS CAM870 - Tune-up guide continue.... 1, File the lower of the chamber to have wider loading angle, also file the top to make it smooth, the new barrel design inside is pretty rough and need to be filed the wall smooth  2, File all corners to make it round a bit prevent scratches and damaged shells end cap, that could be too tough to get jam or struck.  Left one is before filed and right one is after filed  3, File both edge to make it smooth    If you have the first generation bolt, file both left and right side of pushing pin in an angle to help eject even smoother. This is the top view of the bolt  4, File both edge a bit round to reduce the friction when hammer and carrying dog hit through it  5, File smooth the end of the latch to minimize rough contact making scratches and damaged shell end cap when loading. But be careful, don't bend and deform the latches, it will effect the functioning.    6, Clean up the barrel internal Before  After  7, If the shell end cap got scratches or damaged, file it smooth at the bottom and the edge to have it easy to be loaded. you may not have to replace it as long as it's still in shape.  1st and 2nd Gen bolt assembly comparison: Different generation designs usually are for improving products or fixing products used! Since APS released a 2nd Gen new bolt assembly for SF model, and I had a broken pushing pin, so I had to study both and fix mine. I've found that 1st gen bolt has scratch on bolt and the pushing pin with shell guard is too tight close to the 1st gen end cap, it creates narrower ejecting angle, when the shell ejected by the extractor spring, it adds up excessive force on the pushing pin and easy to be broken, that could be the reasons I had it broken. By the mean time, APS had designed a 2nd Gen bolt(that time was not released in the market), even 2nd gen end cap (with wider opening end to allow shell ejected easier) too to make it better. Here is what I've found out. Scratches or rubbing on 1st Gen Bolt  Narrower ejected angle on 1st Gen end cap  Wider ejected angle on 2nd Gen end cap  1st Gen Bolt on right, with narrow spacing between pushing pin  2nd Gen bolt, with wider spacing between pushing pin  End Cap: lift-1st Gen, with narrow spacing. right-2nd Gen, with wider spacing  Pushing Pin - Dimension mearsurements  End Cap - Dimension mearsurements  Shell cup (guard)  Install new pushing pin into 1st gen bolt, 1, you need to drill 4.5mm hole  2, you need to drill widen this slot or file narrow the little shell cup(guard)  All three pushing pins comparison  This is the 1st Gen bolt with modified new pushing pin in it, without the shells cup(guard). Tested fire it, working really well so far, seems like NO NEED to have the shells cup is still not a problem  If you still have the 1st Gen Bolt, you may do it as below to work better with 1st Gen End Cap to prevent broken pin. Of cause, replace the 2nd Gen Bolt is always your best bet!  Trigger set Tune-Up If both of the red contact are not smooth enough, the action bar and trigger connector left would stay at the middle (sometimes) and the trigger might not be fully spring released back in place for next trigger pull.  When hammer up, action bar pushing the trigger connector left up too.  When hammer down, both action bar and trigger connector left will be released back down  Durability Most of the parts are pretty durable and last long, pretty close to RS material excluded the bolt. I don't worry about how many times i rack it. Maintenance Lube internal as usual. I found it's a bit over lubes when new open box. I did clean up excessive grease that not necessary. The only maintain part is the shell. Even if you don't use it much , the o-ring will crack and having gas leak, make sure you have enough replacement o-rings for service. The shell end piece, since l did file the extractor smoother, it's not being damaged as much as before, no need to worry about replacement. Replacement O-ring  Parts support APS has most of the replacement parts available, but still waiting for the new generation of bolt release soon. updated on Oct29:APS has come up some new accessories. Check link below. http://www.aps-concept.com/index.php..._115&limit=100 RatingR1 Because using shells, you should have a shell catcher for gaming. And the gas and bbs reloading is taking a bit long time to do, so you need to have a lot of preloaded shells or long break to reload. For CQB short scenario and using the short version is really good and really fun, for long game, this short version one is good as a secondary.     Diagram

__________________

aka Uncle

Last edited by N_Force; January 16th, 2015 at 11:28.. |

|

|

|

|

|

|

#4 |

|

Maruzen M870 - pump action & M1100 revision - semi auto - duster/green gas shell ejected

Completed on Jan1-2015 more internal pictures will be follow for reference. Design Single inner barrel with non-adjustable hop up. This shotgun has its own unique design. Nothing close to RS but only the look and functioning. It's using most plastic for body and some metal internal. So overall is looking good but light weight. The shells is light and only for loading bb's. Gas tank is located in the stock and detachable, full charge could last around 25 shots. Chance of modifications D4-D5 seems you only can make or customized your own parts. Durability Doesn't last long since there is a lot of pot metal and small parts inside. If you use it for gaming, I believe the weakest part is the join between barrel and receiver. It's not that strong and could be easily get broken when carrying by sling or the force when pumping it. Possible the most easiest wear out parts for M1100 Semi-auto -carrying dog and trigger group  -bolt contacted with carrying dog area   -o-ring sealing underneath gas resovior  -the ejector and both left and right latches   Maintenance I use propane and having gas leak from reservoir and gas line. Those are easy fixed. But I also had a crack piston and been replaced already, now is having eject problem on revision model as it is semi auto. So need to sped some time to find out and get it fix. Taking it apart is not easy tho.... So detail.... Parts supports Not much in the market. Only a few from Taiwan as I found, mostly sold out and have to wait a while for back in stock. Rating R1-R2 It is a fun airsoft shotgun with shells eject. It has a lot of detail small parts inside and the functioning is good. If you take it for gaming, you need to have a lot of shells and pick them back for reload. Each load has 5+1 shells and the gas tank could hold around 30 shots and the firing is not loud, only a light popping sound. Personal I love this shotgun is the unique internal design Japanese engineering, good for my collections. Disassembled Internal for M1100 Semi-auto  M870  M1100 revision

__________________

aka Uncle

Last edited by N_Force; April 11th, 2021 at 11:26.. |

|

|

|

|

|

|

#5 |

|

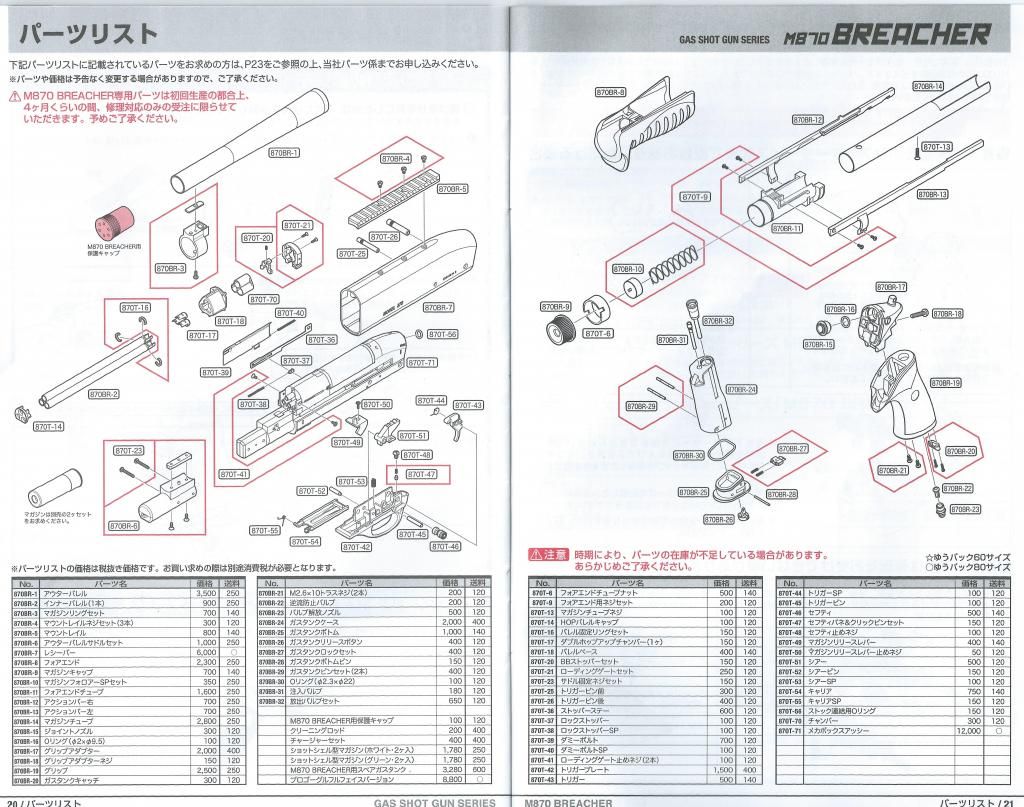

Marui M870 & Breacher - duster/green gas shell loaded

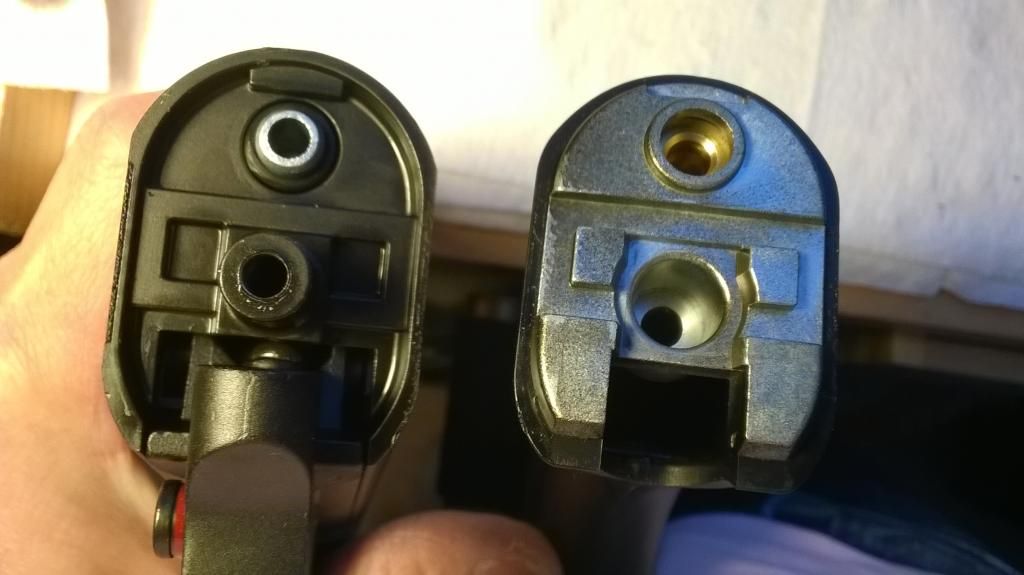

Completed on Dec4 *more pictures and details will be followed if anything new comes up!    Design Three inner barrels with fixed hop up shooting three or six bbs each pump. Gas tank loading at the end of stock can hold 5-6 shells that my gas tank record. One reason I like Japanese engineering for airsoft, is that they use a complicated components to work like, look like and sound like RS. Some of them are good for collection and most of them are good for gaming. Chance of Modify For external accessory, Alot of after market parts are available. Internal, Just for some only. Durability Since all the Japanese airsoft are built for HFC134 gas(70PSI), internal design is just good enough to handle this pressure, not green gas or top gas even propane(120PSI). All internals are used port metal and plastic, so it just last long enough for curtain time of use. Maintenance Lube as regular. But this one is not easy to be dissembled for lubricant. Add right amount for using propane is always needed. Parts Support Some after market internals and alot of accessories. Gaming - R5 Since this shotgun using shell loaded 30bbs and detachable gas tank. So it is 100% good for gaming no matter for indoor or even outdoor. For CQB of cause should go for Breacher cause it is the shortest shotgun in the market that is good for gaming.  Do you see the different between this two gas tanks? Ans: The gas fill valve on Breacher has a new design. It is deeper than the old one. When using AI propane adaptor to fill gas, it fits in deeper and seems like minimize the gas leakage during refill. Compare to WE's has a tiny o-ring in side, this new design seems work better. M870 gas tank  Breacher gas tank  Internal  Trigger Group   Side saddle with its own screws set  AG's choke tube is the closest design looks like RS one  After market Shells compatible (Bravo) As all you know the Bravo shells works with Marui, but I've found that it is not smooth loading the shell into chamber slot. after cut wide and sand smooth the opening, then it works much better.   Fixing gas leak between stock and receiver Since using propane and making the o-ring shrink, then gas leaking. go to dollar shop, buy a box of o-ring in $2, pick one fit into the stock side (right hand side one) and seal the leak perfectly.  Original O-ring  Fixing gas tank flex issue for M870 after added 2 long machine screws to hold the side wall of the tank, you still see the flex issue a bit, and the mag insert is easier, btw, is the propane pressure too high or the port metal too weak?? At lease it look better and easier insert the gas tank into the stock.  Shorten the mag release To prevent accidental release the mag cover and get damage when gaming.  Diagram-M870  Disgram-Breacher

__________________

aka Uncle

Last edited by N_Force; December 30th, 2014 at 14:27.. Reason: Update info's |

|

|

|

|

|

|

#6 |

|

Hwashan Double Barrel - green gas shell loaded / can be modified with Madbull shells in green gas/CO2

Completed on Sept15, Please feel free to ask questions! latest modification for using APS shells, machine made inserts to fit APS shot shell, shoots much louder and fun!      update on Apr-2021 This is the most simplest design one, full metal and wood handle and forend. This gun needs no maintenance. The only thing I don't like is the trigger not spring operated. Means the firing pin is not powered by spring, instead of pulling the trigger to push on the shell value to release gas rapidly. If you pull it too slow, the firing is funny. For maintenance, is only on the shells. Since the shells is made out of metal, I found the early generation has some problems. After certain times of used, the metal or the o-ring got shrink and causing gas leakage. I could replace the larger o-ring or enlarge the size a bit to fill the gap causing the gas leak. Or just purchase the latest generation shells that has better design you'll be fine. **How to recognize the old and the new gen of shells, when removing it in two pieces to refill gas and bbs, the o-ring seal contact for the old gen is a bit loose and wobbling, but the new gen is tight and sit closed.** Design This double barrel is using two inner barrels and the shell loading bb's in one line, and the gas loaded in the shell. So it fires straight and powerful. Because when it fires, it releases all gas in a second, this shotgun is short and not heavy, so you can feel it kick back a bit like recoil. And the front you see the gas release out like smoke. Pretty fun. The down side is no POPING sound when firing, only gas leaking sound!! Chance of Modify A ASC member has this piece modified the inner barrels and use Madbull shells, that even better cause Madbull shell is better quality, more durable and not much maintenance. I saw him using it for gaming tho. pretty nice! I have never tried it, but I think if remove both inner barrels and runs with Madbull shells in CO2, that would be more like the real shotgun, no inner barrel and the bb's spread out wider. Only concern is, when using CO2, the pressure between firing pin and release value will be higher. Could have higher chance to break the firing pin. Durability This shotgun's firing pin so thin and looks not strong enough, will it be broken easily that I can't tell. But based on what he has been gaming it for a while (shows heavily used) and got no complain, seems should be okay! Maintenance As long as you have GBB oil mixed with propane, you'll be fine. When you feel leakage on the shells, check with all o-ring seals just like all the GBBs. Parts support Doesn't look like there is any?? Rating: R3 Since it is using shells, and only two loads each time, for gaming, you need to have a lot of shells loaded and carrying them. Personal, I would like to use it as secondary or back up, it is short and shots 6 bbs, it's really fun for room clearing tho!   Firing pin is pushing not spring powered  Shell is separated in two pieces, bbs loading side and gas loading side  left side has the inner barrel removed and right side is original inner barrel  the right side, once removed the inner barrel, you can see the front looks like the real steel, wide opened.  Hand grip top and bottom

__________________

aka Uncle

Last edited by N_Force; April 11th, 2021 at 12:09.. |

|

|

|

|

|

|

#7 |

|

Marushin Mossberg 500 - duster/green gas powered

Completed on Jan1-2015 Design This is also one of a full metal Japanese version, with nice handling weight, realistic clicking sound when racking it, single inner barrel, shooting with 5 6mm bbs each time. Spreading bbs not as good as Marui M870. Using 3 bb loading tube that holding 50bbs each, store inside shell tube, giving you 10 pump each x3, every 10 shots your have to turn the bb loading tube for next 10 shots, having 30 shots per load. Then you have to reload bbs to all three of the loading tubes and also refill gas. It's a disadvantage since there is no bbs loading tube exchanged and even it is internal gas reservoir, not exchangeable. This model has a Chinese made available in the market and seems most internal parts are compatible. Chance of ModifyD1-D2 This piece here is the only one I bought it used and had gas leak when I got it. Seems like the gas leak is still the most common issue that most of the Japanese version has (design to be used HFC134 gas). In the Taiwan market has original parts and after market parts available once in a while. I tried the Mosquito air outlet valve, but couldn't make it works the best, finally I got back the original one working good and fixed the leak. Also you can find loading arms and hammer set. But I heard that the China made M500 clone model could work tho since I don't plan to get one and I don't have one. Durability Pot metal is being used and just like the rest of our airsoft guns. Maintenance Need to have basic lub and maintenance. Parts support There is parts available in TW once in a while, like loading arms, hammer set and valve set. RatingR3-R4 Since it is only have 30 pumps of bbs can be loaded, for CQB should be enough, but for long game you may have to carry gas and bbs around to fulfill whole day needed. Three bb loading tubes pull out from shell tube, the top knob is for turn to change the bb loading tubes use  opening slot is for bb reloading, right underneath the shell tube when moving loading arm to back  Trigger set, this is one of a design I like, "realistic hammer function" to engage gas release.  Interal reservoir, good enough for a bit less than two full bb loaded. Part 80 inside it, is the one got leaking gas the most problem one. replaced with needed. No big deal  bb loading mechanism disassembled inside gas reservoir.  From top, shell carrier piece, eject port cover, loading arms, gas reservoir and trigger set assemble.   Reference Diagram

__________________

aka Uncle

Last edited by N_Force; January 1st, 2015 at 14:24.. Reason: update info's |

|

|

|

|

|

|

#8 |

|

Airsoft (氣槍), I believe started from US & Europe earlier some time, then in Japan around 70-80's as far as I remember. I was so impressed Japanese engineering when I was teenage. Owned a lot of Tamiya models. Then airsoft came into Asian market. It was so nice and made by plastic body with some metal internals. The body design was based on RS with trade, and functional also. That time there were no blow back function. From time to time, they improved it not only the look more like RS, but also function like RS too. Because the power was using 134 gas, this Japanese engineering designed the internal so complicated and detail to make out the functional similar with RS as well, some with shells and some don't. If you've disassembled those Japanese airsoft guns, you will know what I mean. As of the market is changing, asian market turned this design into metal base from body to internal. Now not only the look, the internal, the functional, the weight, even the power and sound. Fulfill most of our airsofters and collectors needed!

PS: I know there are original parts available in Japan for its own products but not available outside Japan most likely. Only some from Taiwan, unless you can get connection or source direct to Japan. Shotgun Comparison Chart *This is based on personal experience, and it is for a reference only.  APS CAM870/Custom SF   Hwashan Double Barrel  Marui M870/Breacher  Marushin Mossberg M500  Maruzen M1100 revision semi-auto  Maruzen M870  Tanaka M870

__________________

aka Uncle

Last edited by N_Force; April 11th, 2021 at 11:35.. |

|

|

|

|

|

|

#9 |

|

butthurt for not having a user title

|

Goddamn. +1000 points of encouragement to complete this post.

|

|

|

|

|

|

#10 |

|

|

|

|

|

#11 | |

|

Oh we do hate you, just never felt like wasting the time to give you a user title :P

|

agree, always wanted a gas shotgun, even if for just plinking. Aside form finding the holy grail (ie a tanaka) this will be a good source if info to help with selection.

looks good so far cant wait to read more, in fact just cause im impatient ill ask one question, how do you find the hwashan as far as durability and functionality and also is it more or less the same as the kjw mad max shotgun? Thanks in advance, ill he watching for more updates

__________________

Quote:

FinchFieldAirsoft |

|

|

|

|

|

|

#12 |

|

Great information! Thanks uncle

|

|

|

|

|

|

|

#13 |

|

Thank you - nice write up - can't wait for the complete reviews

__________________

M4 MK12 MOD0, SBR, KC02 G17 (B. A. Level 2 Cert.) |

|

|

|

|

|

|

#14 |

|

Makes me want all the shotguns..

|

|

|

|

|

|

|

#15 |

|

Definitely going to look for that APS

Any good retailers with good price you know of? PS: great write-up,thanks! |

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|