|

|

|

#31 |

|

Ok,well I ripped apart my M90 cyl. and checked the tention on that screw and sure enough,it was backed out about 1/4 of the way aready! Thanks guys for the heads-up,Cheers!

P.S. I sprayed both parts with motor solvent(for electric motors) too clean them(they needed it),too make sure the 242(Loc-tight) takes hold.Don't worrie I didn't spray any of the other parts as that stuff can eat plastic,and or make it brittle.

__________________

Death Before Dishonor" Bleeding Black Label" |

|

|

|

|

|

|

#32 |

|

Here's what I did, hope it's right...

Unscrew the nozzle-end of the cylinder (some people recommend starting with the opposite end first), remove the nozzle-head from the piston head ( just pull them apart).

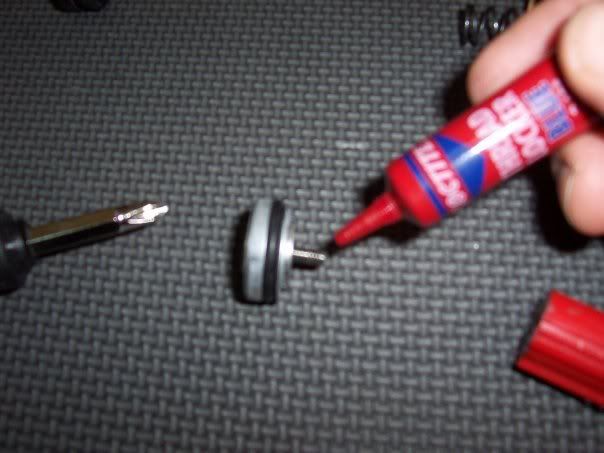

Next, remove the piston head from the red guide & rack. Some cylinders have the threads on the piston head like mine, others are on the cylinder guide.  Last, loctite the threads indicated in the photo, and reassemble everything in reverse order. Pay particular attention to re-inserting the red guide-thingy (yes, that's the technical term for it) as it must be aligned with the guides inside the cylinder, or else it won't go all the way in.

|

|

|

|

|

|

|

#33 |

|

PTW cylinder maintenance...

Good thing I decided to pull apart all of my cylinders to clean & inspect...

Found the following: - loose screws = Loctite applied. - lack of factory lube = Systema cylinder grease applied. - o-rings were very dry & required some lube. This is something that should not be overlooked if you own a PTW.

__________________

Kevorkian  I SUPPORT THE USE OF SILICA BB BASTARDS! |

|

|

|

|

|

|

#34 |

|

Regular cylinder maintenance is key to smooth operation. I tear my cylinders down after about 10,000 rounds or so, or about twice per year for the M130 and M110, and I haven't yet for the M90 or M150s. Replace the nozzle o-ring and re-lube at a minimum, and maybe every year or 2 replace the piston head o-ring and bumpers.

You could just do the whole rebuild kit for $12 and do it all, but I haven't found the need for that yet. The nozzle o-rings are the ones you need to be religious about.

__________________

Age verifier Northern Alberta Democracy is two wolves and a sheep discussing what's for dinner. Freedom is the wolves limping away while the sheep reloads. Never confuse freedom with democracy. |

|

|

|

|

|

|

#35 |

|

I've purchased the rebuild kits but have yet to use any of the parts as all I needed was lube & Loctite...for now, but I was wondering where the small, black o-ring in the rebuild kit is to be used? I did not come across this part when performing my cylinder maintenance today!!!

__________________

Kevorkian  I SUPPORT THE USE OF SILICA BB BASTARDS! |

|

|

|

|

|

|

#36 |

|

Are you talking about the nozzle o-ring? I don't know of any small o-rings other than that, but they did a cylinder change last year for 2008 and all my cylinders are pre-2008, and none of them have it.

Old cylinders screwed the piston head on from inside the cylinder. New ones from inside the piston head itself, like in the pics above^.

__________________

Age verifier Northern Alberta Democracy is two wolves and a sheep discussing what's for dinner. Freedom is the wolves limping away while the sheep reloads. Never confuse freedom with democracy. |

|

|

|

|

|

|

#37 |

|

Official Crybaby Chairsofter

|

My M150 was factory tested. My M90 has a completly different design... shoulda taken pictures it was wierd and a very impressive system.

|

|

|

|

|

|

#38 |

|

I also have new cylinders all the colors but I haven't openned them up yet because I already got a few used ones that are good to go...but I will have to check for locktighting that loose screws with those new cylinders...

|

|

|

|

|

|

|

#39 | |

|

Quote:

Have a look at the cylinder rebuild kit I got from Jugglez...you can see the small BLACK o-ring, just don't know where it belongs & if it's needed!

__________________

Kevorkian  I SUPPORT THE USE OF SILICA BB BASTARDS! |

||

|

|

|

|

|

#40 |

|

The only thing is behind the piston head spring guide. I can visualize the rest of it in my head, but it doesn't look like it goes anywhere else.

I looked at the cylinder breakdown. I goes in the cylinder head, between the nozzle spring and the head itself. I can't imagine why the hell you'd need to change it.

__________________

Age verifier Northern Alberta Democracy is two wolves and a sheep discussing what's for dinner. Freedom is the wolves limping away while the sheep reloads. Never confuse freedom with democracy. Last edited by mcguyver; February 5th, 2008 at 03:13.. |

|

|

|

|

|

|

#41 |

|

My thoughts exactly! Do you know of any exploded view diagrams pertaining to the PTW cylinders?

__________________

Kevorkian  I SUPPORT THE USE OF SILICA BB BASTARDS! |

|

|

|

|

|

|

#42 |

|

Go to the PTW-users website and download the .pdf for Technical Illustrations. It has the parts list and exploded diagrams.

__________________

Age verifier Northern Alberta Democracy is two wolves and a sheep discussing what's for dinner. Freedom is the wolves limping away while the sheep reloads. Never confuse freedom with democracy. |

|

|

|

|

|

|

#43 |

|

I was amazed last week when I took my cylinder apart and relubed it how much of a difference it made in terms of performance. I noticed a much tighter grouping and much longer distance of effective range. I didn't replace the o-ring yet cause it was just a "lunch time, lets try something" kind of maintance since its been somewhere around 10000 rounds through it now since new.

__________________

South Island Rangers Airsoft Club- President Victoria Area Age Verifier |

|

|

|

|

|

|

#44 |

|

Good to hear, these were my exact results as well after completing my cylinder maintenance! My groupings were tighter as well...everything sounds smoother!

__________________

Kevorkian  I SUPPORT THE USE OF SILICA BB BASTARDS! |

|

|

|

|

|

|

#45 |

|

Guest

|

You know, I think we need a PTW FAQ including diagrams, all the available documentation and maintenance schedules / procedures. All in one nifty place...Anyone up to it?

|

|

|

|

||||||

| Bookmarks |

|

|

|