|

|

|

#31 |

|

Have you done this on your own G18 with any successful results?

I cut the piece down far enough that even with the spring fully compressed the plunger stays covered by the spring

Last edited by Shrapnel[Op-For]; February 1st, 2013 at 23:37.. |

|

|

|

|

|

|

#32 |

|

Ohhhh that's what you meant by a plunger, I'm not sure what the correct term for it either but I heard a local gun doc call it a spring guide. Makes sense that being on the longer side, it would break the nub off during fast cycling especially when cold from full auto fire.

|

|

|

|

|

|

|

#33 | |

|

will always be Mike Litoris in our hearts

|

Quote:

Can you tell I got a WE G18c haha |

|

|

|

|

|

|

#34 |

|

For all of you who want spare nozzles/plungers and nozzle return springs, PM me. For all those who have already PM'd me, check your inboxes tomorrow.

|

|

|

|

|

|

|

#35 |

|

Yes. My loading nozzles now only break due to the high internal pressure created during the cycle. Yay for good seals and high output blowoff valves. They literally explode!!! But that nub stays unbroken with this mod done....

__________________

"May you fight with the strength of ten full grown men." |

|

|

|

|

|

|

#36 | |

|

Quote:

So your nozzle still breaks regardless? |

||

|

|

|

|

|

#37 | |

|

Quote:

So if there isn't enough power to spring to resist the recoiling slide, the nub will slam against the the plunger. AND if the plunger is too long, the force of the recoiling slide will shear the nub right off... Your worry of the spring crimping is valid. However, there are many BBUs that don't accomodate a plunger for that spring and they still stay relatively undamaged during operation. THe Glock 17 for example doesn't have a plunger. Nor do the hi-capa nozzles and they stay uncrimped for a long while (at least in my guns). But in general terms, most GBB pistols crimp that spring regardless of how much caution each operator exercises. It's common. This is why there aftermarket companies that carry replacement loading muzzle springs in their brand line up. You have to cut it to the right length. As long as you don't cut it too short that the plunger's function becomes non-existent, you're ok. That is, don't cut it too close to the "base" or the fat part where the spring rests against... All loading muzzles eventually break in any GBB pistol (or even GBBRs). This is just the nature of the loading muzzle. Sometimes they even break in areas that you think is the sturdiest. For example, the loading arm might break or the actual air output part of the muzzle where it is the thickest may crack or even the body of the loading can fall apart under heavy pressure. On the Glock 18c, the nub is the most common area of breakage because of that plunger....

__________________

"May you fight with the strength of ten full grown men." |

||

|

|

|

|

|

#38 |

|

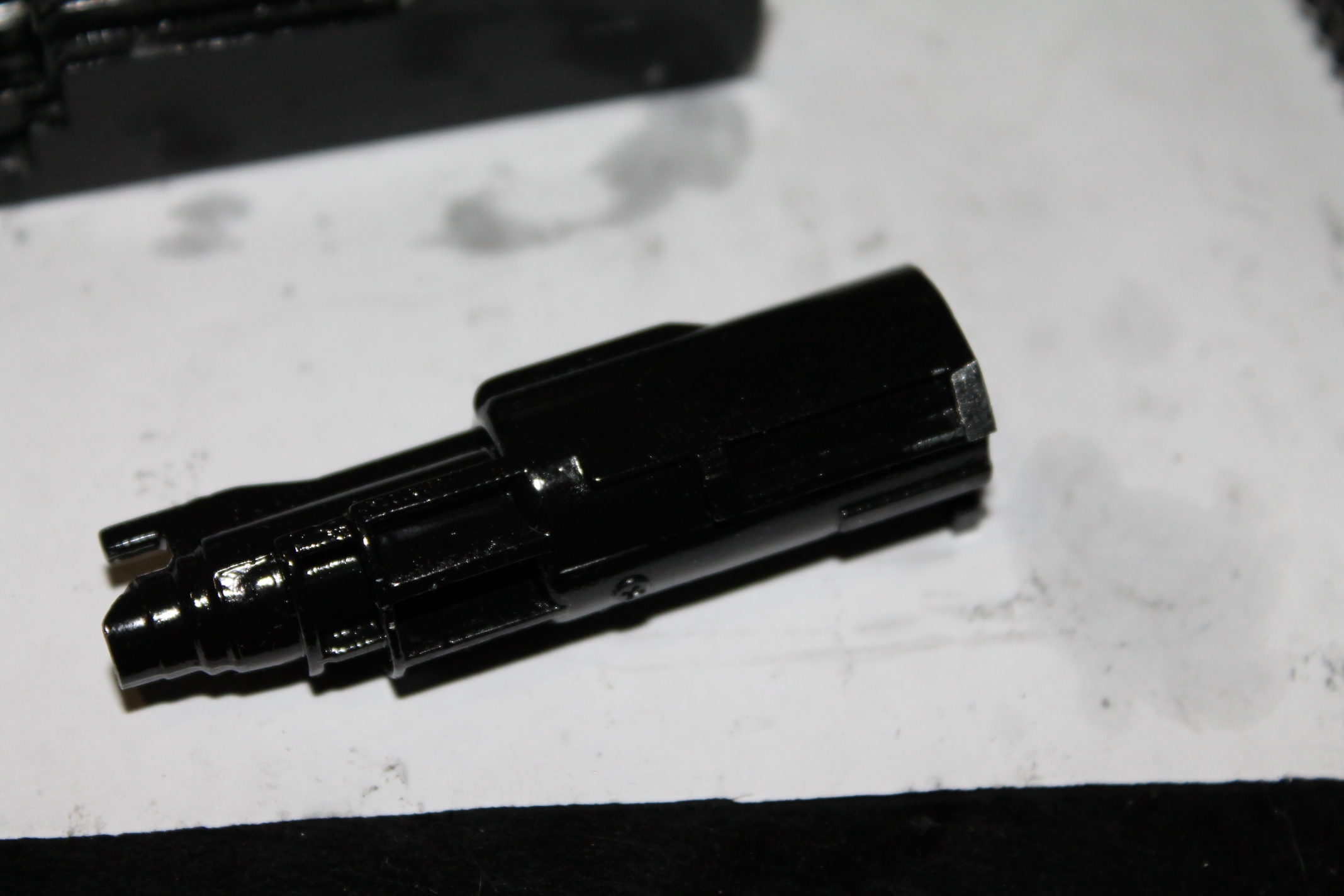

So judging from my photograph, would you say the guide rod is cut short enough?

|

|

|

|

|

|

|

#39 |

|

Can't say for sure but I wouldn't cut it any shorter unless you break another loading muzzle. I can't really tell you a valid answer to that considering I don't have your gun in front of me. Plus, I need to know how strong the spring is and how your gun cycles to be able to make, at least, some sort of educated guess....

My Advice to you is to observe you how the muzzle is behaving everytime you charge your gun. If you see that the hop up unit is holding unto your loading muzzle a bit, shorten the plunger. If it doesn't then you won't need to since the slide will carry the loading muzzle at all times. But the latter is a clear indication that the spring is usually crimped and not functioning properly....

__________________

"May you fight with the strength of ten full grown men." |

|

|

|

|

|

|

#40 |

|

Ok so a bit of an update. I installed a new loading nozzle (stock WE g18) and replaced the crimped return spring with a fresh one. It seems like with the cut down guide rod the gun is cycling properly without the spring becoming crimped. So far so good. I went to go test fire a few mags to see how the nozzle would hold up but now the gun won't even shoot properly. It is venting all the gas in my mags after one shot, doesn't matter if its one full auto or semi. I have three different magazines, all new no leaks and they all do the same thing. So now I can't even test the guns durability because it won't fire without spewing propane everywhere. Someone help?

|

|

|

|

|

|

|

#41 |

|

Did you put the floating valve back in? Without it inside the nozzle, there's nothing to seal off the gas after each shot.

|

|

|

|

|

|

|

#42 |

|

|

|

|

|

#43 |

|

So I put the floating valve in, but with a mag in the gun it begins to release the gas on the first shot, just now with the valve in it doesn't spew everywhere...

|

|

|

|

|

|

|

#44 |

|

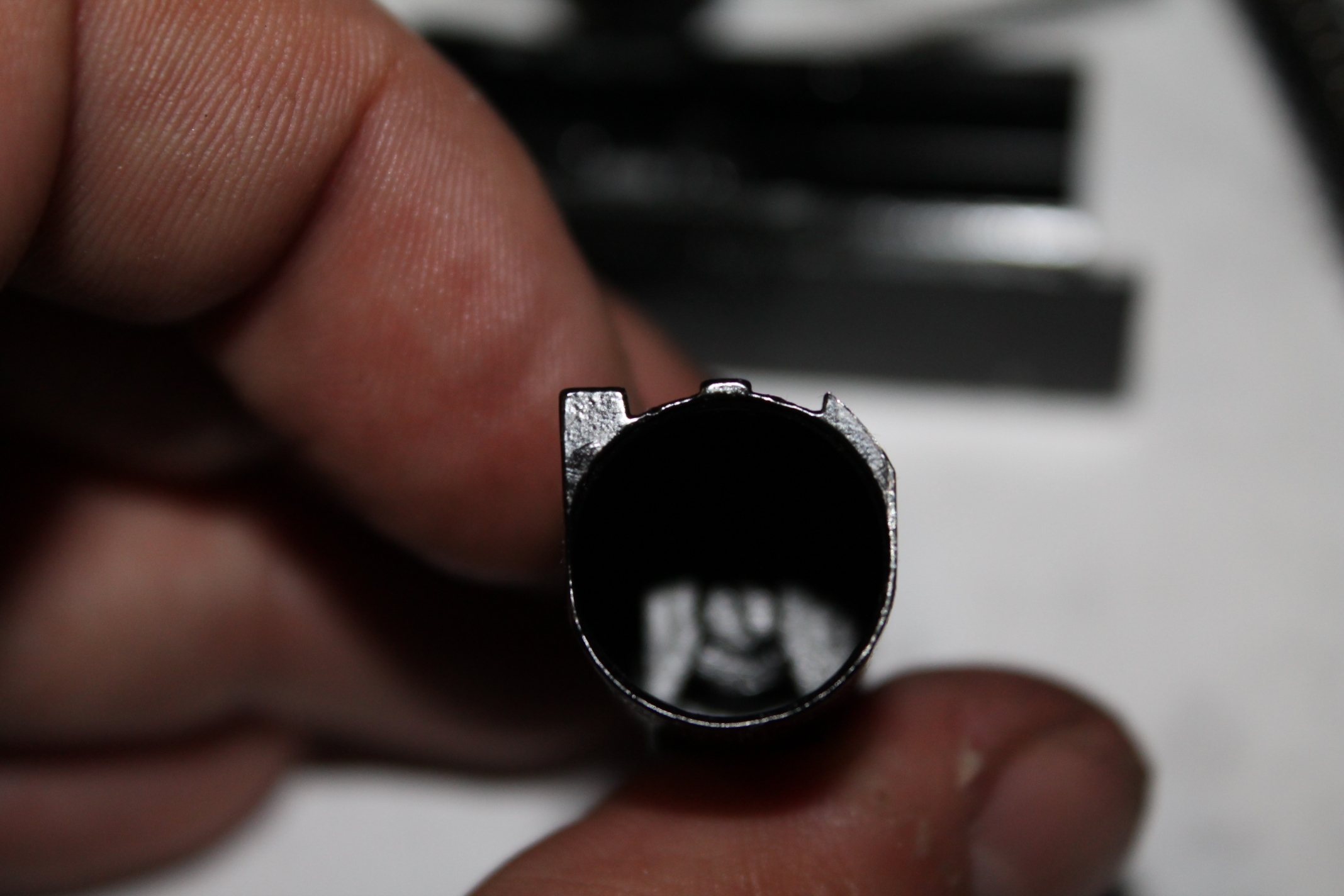

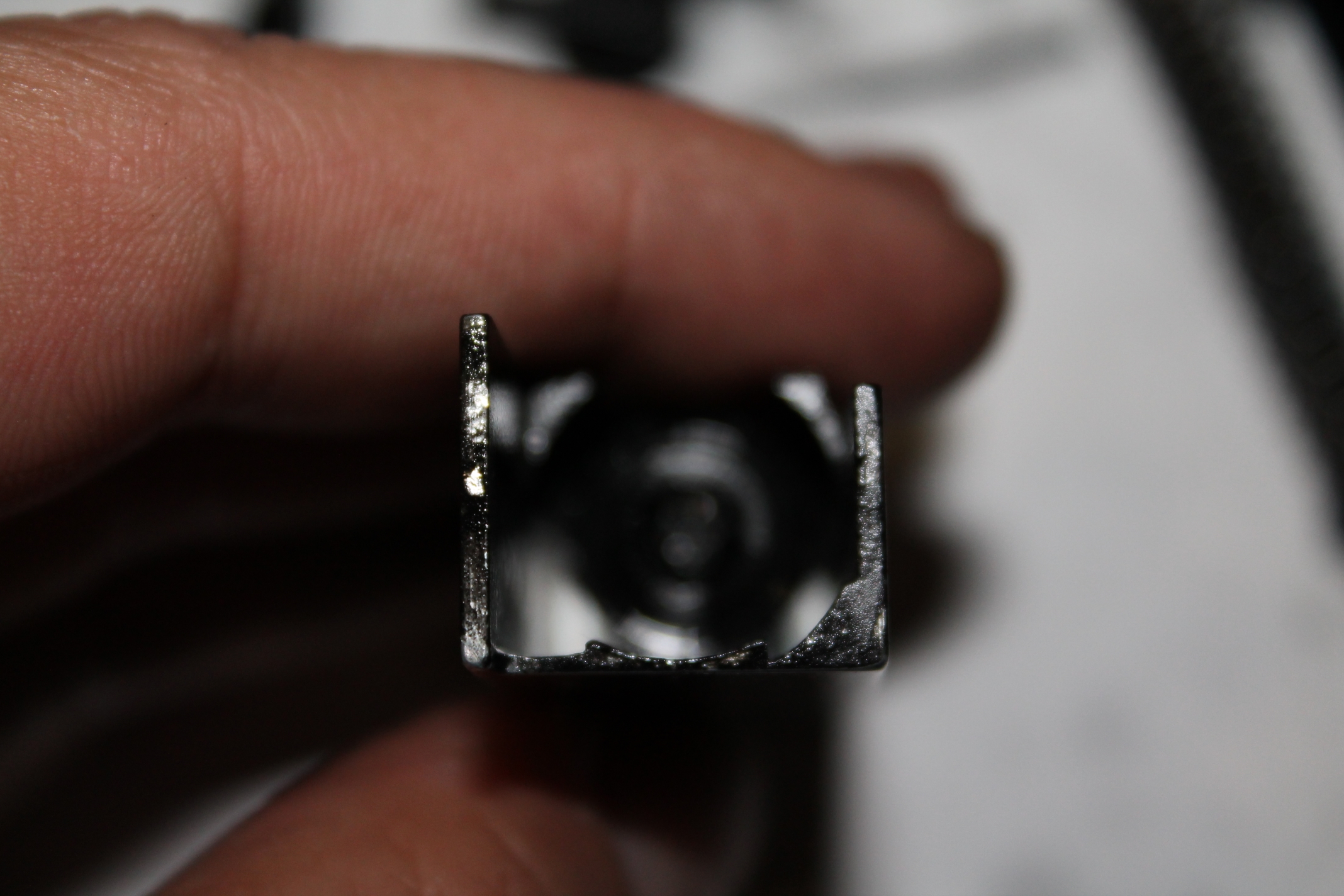

After breaking several myself, I added a TM G17 loading muzzle to an order and got a caliper and checked the differences. There is a 0.2mm difference to the internal diameter so the piston head did not fit. the only other difference is a nub, like the one breaking off. I filed it off and checked the fit without the piston head and it fit well.

I then ordered a full metal replacement set (for a TM g17) and after filing off the extra nub, tried to install it but the new, correct sized piston head but it was too thick and wouldn't allow the nozzle to go back completely. I then took a razor blade and shaved off some of the rubber on the stock piston head until it moved with minimal friction. I reassembled the pistol, lubing it up as i went along. I tested the mechanism by putting loading 3 50 round mags and racking the slide and it feeds perfectly. I then put a 25 round mag through it with no issue. Ii ill be testing it this weekend and will let everyone know how it holds up. The mod, btw, cost less than a new WE loading nozzle. $16 shipped from Hong Kong. The filed off nub.  Loading nozzle end view.  Loading nozzle must fit smoothly.

Last edited by AdamBenoit; July 13th, 2013 at 01:29.. |

|

|

|

|

|

|

#45 |

|

no go

So, it works, sort of.

It will fire a mag, maybe 2, then jam. I tear it down and find more rubbing. I file it down, and it fires a mag, then jams. So it may work if I wanted to spend more time, but I don't. But it doesn't seem worth it at this time. It seems we will have to wait for a 3rd party solution, hopefully in metal. |

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|