|

|

|

#16 |

|

I was thinking of just making it out of clay or playdough. Then hardening it in a kiln. Then getting it powder-coated.

__________________

|

|

|

|

|

|

|

#17 |

|

if you are able to measure it correctly and draw it with a CAD, that company look very interesting. very accesible for everyone i think

http://www.emachineshop.com/ |

|

|

|

|

|

|

#18 |

|

You know getting a formed shape made out of carbon fiber and then affixing it in layers would could be upwards of 10 times stronger than steel. Thus a 1 mm thick layer of good quality CFRP would be equal to a half inch of standard steel at a faction of the cost.

Just saying. |

|

|

|

|

|

|

#19 | |

|

Quote:

__________________

|

||

|

|

|

|

|

#20 |

|

you can't make threads in carbon fiber. but you can make holes and put in some metal inserts that are threaded

|

|

|

|

|

|

|

#21 |

|

I was talking about reinforcing the striking plate face with carbon fiber to increase it's durability and help distribute shock across the entire face. The part fails because it is incapable of adequately distributing the load across the entire surface.

Using carbon fiber allows for maximum strength with minimal size change and weight addition. just a suggestion. |

|

|

|

|

|

|

#22 |

|

the bolt doesn't strike that piece. it's a square frame that the hinge plate slides over, and has the sling attachment points on both sides.

except it's pot metal, and gets quite a bit more force with the open bolt kit, and will eventually break because it bears the rest of the hinge plate force. EXCEPT if you do the pvc block mod in the lower receiver XD

__________________

Current Gear: TM G36C/SL-9, WE M14, WE PDW, KWA USP, KJW USP Tactical Future Gear: TM PSG1, M700, ARES DSR-1 v2 |

|

|

|

|

|

|

#23 | |

|

Quote:

I looked at it again. My bad. |

||

|

|

|

|

|

#24 |

|

Could do that on a CNC mill if you had a DWF or similiar file. Get it drawn up.

email this guy onemancnc@hotmail.com His name is Darryl. Give him the drawn up part and he can do the rest, I know this for a fact. Beware 1 off's are exceptionally expensive due to setup time. Look at batch order, 10 off or more. Billet machining from something like 410 stainless or D2 tool steel os simililar, that way your receiver will shatter into 10,000 pieces before this part breaks. Pete

__________________

|

|

|

|

|

|

|

#25 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

You guys are looking for a machinist and you don't even think of me, you guys are dicks.

Get me a good high detail picture of the part, I'd like to know if it would be something worth making for me, or if I could repair and reinforce it... |

|

|

|

|

|

#26 |

|

I thought of you frank, Actually I did text you about finding a good machinist in winnipeg for this. I just bug you a lot as it is. Ha ha.

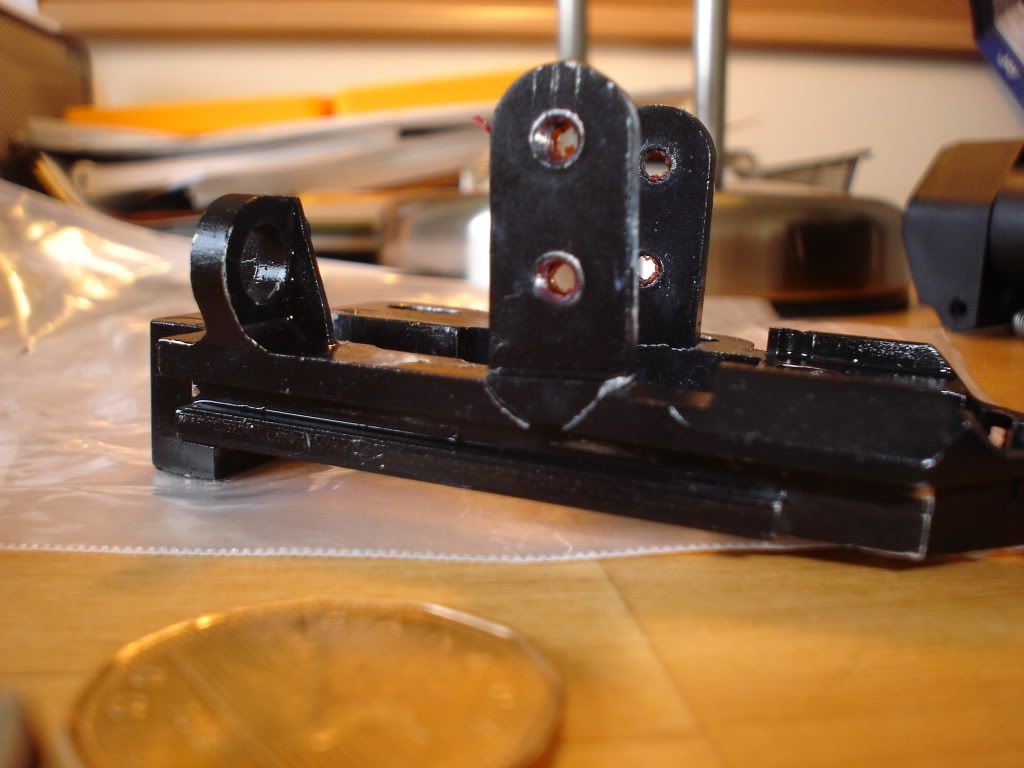

this is the broken piece. I have amos bugging ra-tech to bug WE to get 2 more replacement ones. When they come in, I can just give you one.

__________________

Last edited by Ross; March 18th, 2011 at 10:12.. |

|

|

|

|

|

|

#27 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

yeah that's a tough one alright

|

|

|

|

|

|

#28 |

|

I was thinking of soldering little pieces of aluminum plates on these areas. Don't know how well it will work. Someone also suggested using metal glue.

__________________

Last edited by Ross; March 18th, 2011 at 12:27.. |

|

|

|

|

|

|

#29 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

You'd have to groove out all the material and braze all the way around, leaving fair sized radii on the corners

I just don't think you could put enough filler material in to make it solid and have it fit back on the gun.... |

|

|

|

|

|

#30 |

|

Ross I've got your 2 parts inbound

|

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|