|

|

|

#31 |

|

I love you amos.

Are you talking about my mod, or your cncing?

__________________

Last edited by Ross; March 18th, 2011 at 12:54.. |

|

|

|

|

|

|

#32 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

talking about fixing the broken one

I can machine anything once, but it would take too long and you wouldn't want to pay that much for it lol |

|

|

|

|

|

#33 | |

|

Suburban Gun Runner

|

How many would it take to make the price realistic? I'm sure there are enought SCAR users that would want a Steel part #27 to make it feasable.

__________________

Quote:

|

|

|

|

|

|

|

#34 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

Honestly, I'd have to get the company I work for to actually produce it lol

Like laser, bend, machine, etc. Casting isn't strong enough and asian companies don't seem to understand that... |

|

|

|

|

|

#35 |

|

well bollocks. I'm just going to have to try my solder idea, and if that breaks still, I'm doing the pvc mod.

__________________

|

|

|

|

|

|

|

#36 |

|

Do you guys think that expressing common interest in a steel upgrade to after-market parts companies (I'm thinking RA Tech here) could get it produced?

I'm guessing their steel bolt + slide (or however its called) kit will destroy quite a few of these, if their previews are to be believed. |

|

|

|

|

|

|

#37 |

|

Yeah, they probably would. But it would take them forever. They have told me they are making a cnc steel part 66. But that was a month ago. About the same time they announced the steel bolt assembly.

__________________

|

|

|

|

|

|

|

#38 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

I just said brazing wouldn't work, soldering isn't half as strong as brazing lol

|

|

|

|

|

|

#39 |

|

I'm sorry thundercactus, I didn't know what brazing was. I'm not repairing the broken piece, I'm reinforcing a brand new one. It would be better than not reinforcing it, and it's more like an experiment.

__________________

|

|

|

|

|

|

|

#40 |

|

Not Eye Safe, Pretty Boy Maximus on the field take his picture!

|

oh, well in that case, use silver solder at the very least

|

|

|

|

|

|

#41 |

|

as a possible alternative, maybe a machined part that combines the hingeplate AND part 27? you'd lose the quick disassembly, and you'd have to unscrew the 4 screws on either side of the main frame for bolt access, but if it was all one piece, breakage would be much less of an issue.

__________________

Current Gear: TM G36C/SL-9, WE M14, WE PDW, KWA USP, KJW USP Tactical Future Gear: TM PSG1, M700, ARES DSR-1 v2 |

|

|

|

|

|

|

#42 |

|

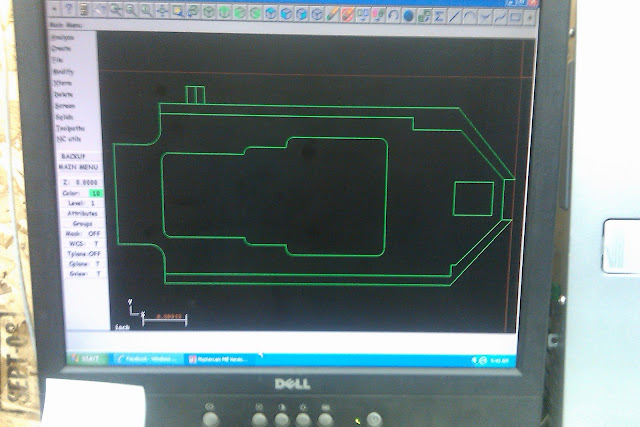

hey guys i just joined the forum due to this topic here, i live in michigan and i too have broken part 027. i cant get one anywhere and its quite dissapointing. However, my old man has his own home business making billet aluminum cnc parts for 1/5th scale RC cars :-) ive been talking to him about this part and hes gonna let me design and make a part on one of his three machines, it may take me a while like month or less, but i hope to get one made soon i started drawing it up in mastercam tonite. If i can make one (not sure on how much it would cost right now) but would anyone be interested in one? i too was thinking steel but my old man seems pretty sure 6061 billet aluminum would hold to more than what the gun can put out. Dire_Wolf i like your idea i might have too look into that. also i was thinking of omitting the two sling loops on the left side of #27 and keeping the one on the right, just to keep the part simpler faster and cheaper.

So ive drawn what i can so far in one night, and ill get a pic of it so far, but in order for me to continue drawing and programming im gonna need a part that isnt broken, does anyone know where i can get one, ive contacted WE twice now with no reply, and ra-tech doesnt carry them, theres a website in the UK that carries them but is out of stock. So if you guys could help me get one ill continue with the programming. Also before i go, Would you guys prefer something like Dire_Wolf suggested? make the stock hinge, and part 27 all one piece? because to me that makes logical sense, it makes it simpler, probably a little cheaper, and you wouldnt have to worry about breaking stock hinges anymore either. But the downfall is you wouldnt be able to strip the gun as quick. Let me know, Thanks

|

|

|

|

|

|

|

#43 |

|

I would prefer to have the piece separate just for the take down ability but if it's the best way to do it, I would take a combined piece as well. I know ra-tech mentioned that they are making cnc'd part 66's. I would buy this off of you as long as the price isn't ridiculous. The only way to get a replacement part is through WE. And WE only answers emails to retailers. So you have to convince a retailer to get one from we. Amos has somehow gotten ra-tech to get this piece from we and ship it out to him.

Aluminum would work great. Make sure you are able to test the piece out before mailing it off. I think the fastest way for you to get your hands on a non broken piece would be to borrow a friend's scar.- thanks for your interest.

__________________

Last edited by Ross; March 22nd, 2011 at 12:10.. |

|

|

|

|

|

|

#44 | |

|

Quote:

|

||

|

|

|

|

|

#45 |

|

i think there would be quite a few interested parties, for either method. Personally, if I didn't have to worry about breakage, i wouldn't be taking down the gun quite so much.

Also, given the complexity of disassembling an AEG, even adding 4 screws instead of a sliding piece doesn't make it even close to an AEG. that being said, a direct drop in replacement... for BOTH pieces... would likely be the best received solution. If i can borrow my dad's vernier caliper, i could get you some measurements of mine, either 27 or 66. Regarding the sling points... I'm right handed, and I would LOVE having the attachment point on the left of the gun, so I can use a bungee or ms2 sling and have it hang in front of me. The current points aren't large enough to allow it without a keyring or something. so even taking the existing holes and making one of them larger, same shape but more material and larger opening, i think would be a good idea. However removing the left points entirely? :S not sure how many people would like that... Now that being said, if you're designing BOTH parts, you don't have to use the exact same dimensions... you can make the sliding grooves larger to reduce breakage.

__________________

Current Gear: TM G36C/SL-9, WE M14, WE PDW, KWA USP, KJW USP Tactical Future Gear: TM PSG1, M700, ARES DSR-1 v2 |

|

|

|

|

|

|

||||||

| Bookmarks |

| Thread Tools | |

|

|

|