|

|

|

||||||||

|

|

|||||||||

| Home | Forums | Register | Gallery | FAQ | Calendar |

| Retailers | Community | News/Info | International Retailers | IRC | Today's Posts |

|

|

|

Thread Tools |

|

|

#916 | ||

|

GBB Whisperer

|

Quote:

Quote:

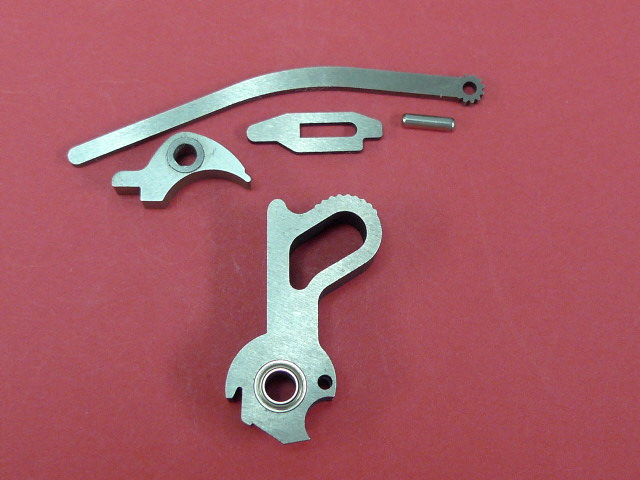

The easiest fix I've found for this is to just increase the strength of the trigger disconnect lever spring. This is the right-most prong of the leaf spring. Push that prong forward to increase strength. This is usually enough to give the lever that much strength to push up behind the sear. If that still doesn't work, the other fix is to file a gentle ramp in to the back of the sear to allow more room for the disconnect lever to slide up behind the sear. |

||

|

|

|

|

|

#917 | |

|

Quote:

I posted the fix on Arnies before: http://www.arniesairsoft.co.uk/forum...post&p=2364375 FYI this problem can and does happen on completely stock gun, and is onething I consider as a potential designed flaw of the system. It was no coincidence I think I HAD to do this mod on all 4 of my Hi-Capa/1911 eventually. Last edited by RacingManiac; February 24th, 2011 at 11:09.. |

||

|

|

|

|

|

#918 | |

|

GBB Whisperer

|

Quote:

|

|

|

|

|

|

|

#919 |

|

Nowadays I am less worry about that since TMC stocks quite a bit of stock TM parts and you can get steel disconnecter....though TBH I have not had reasons to spring for one yet...

|

|

|

|

|

|

|

#920 |

|

So, I have been planning on building myself a custom 1911 for quite some time, and there is still one question that I have yet to sort out. I decided I would go with a full-length guide rod, as I have heard that this could help get rid of some slide-wobble.

Now, the parts I have picked out are linked below, but I can not figure out if there is a specific barrel bushing to be used. Nova has, iirc, 3 different designs of bushings, and an equal number of recoil spring plugs. Should I just match up (in this case) type 3 with type 3, or can I mix-and-match? LCT – Stainless Steel Recoil Spring Guide NOVA – Stainless Steel Recoil Spring Plug (Type 3) |

|

|

|

|

|

|

#921 |

|

The "types" are just style of bushing. They should all work regardless. Some are thicker flanges, some are thinner. And as far as guide rod bushing goes the, just make sure the one you want are through-hole type....

|

|

|

|

|

|

|

#922 | |

|

GBB Whisperer

|

Quote:

The difference between the barrel bushings are cosmetic: - Type 1 is "Government" style. It's what you'll find on the majority of modern factory builds. Kimber builds use something like this. Looking from the front, the sides are flat, and the legs that protrude down to lock to the spring plug are a bit longer than the other styles. - Type 2 is a "Series 70" style. The legs that lock to the spring plug are stubbier, and the overall thickness is a bit more than the Government. It provides a much more pronounced side profile. Looking at it from the front, the sides of it are a bit more rounded than the Government or Caspian style. - Type 3 is a "Caspian" style. Thickness is on par with the Series 70 style. Looking at it from the front, it has flatter sides like the Government style, and the legs that lock to the spring plug are also longer than the Series 70 style. The differences between the Type 3 and the Type 1 legs, is the Caspian style has a flat bottom to the legs. Caspian bushings are used on a lot of custom built 1911's. Again, it is cosmetic, and you will need to judge for yourself which one you'll go with. But for all intents and purposes, they will work interchangeably. The difference between the spring plugs is functionality: - Type 1 is your standard plug, for use with a shortened recoil spring guide, straight barrel, and barrel bushing to lock to it. - Type 2 is for use with full length guide rods and bull barrels. Barrel bushings can not lock to it. - Type 3 is for use with full length guide rods, straight barrels and barrel bushing to lock to it. |

|

|

|

|

|

|

#923 | ||

|

Quote:

Quote:

Thanks for the tl;dr version. |

|||

|

|

|

|

|

#924 |

|

Just curious, how come stock/aftermarket hammers for TM Hicapas have a much longer hook than ones for WAs, which is literally as short as rs? Is it because the WA trigger/hammer assembly closely resembles rs and thus is more efficient?

|

|

|

|

|

|

|

#925 |

|

No idea, however I much prefer the pull on the TM for some reason vs the WA. I have 1 1911 and 1 2011 of WA and 2 of each for TM and all have aftermarket sear/hammer/trigger componentry(very similar, wire-cut steel parts, may or may not be the same "shop"). And I can't for the life of me to get them to feel the same clean break as on the TM. There always seems to be more "creep" in the WA.

|

|

|

|

|

|

|

#926 |

|

GBB Whisperer

|

I couldn't say for certain, but I would guess it has to do with the different location/distance and angle-of-engagement of the hammer to the sear in the TM vs WA/RS. While TM generally does a decent job of replicating the external outlook of real world guns, they are notorious for designing internals their own way to keep the product unique and maintain product patent integrity.

|

|

|

|

|

|

#927 | |

|

Quote:

My tm MEU had this same exact problem (stock one). I did this mod (though I didn't take much chunk out of the metal like you did) and the 'dead' trigger pull is gone! I will surely do this mod to the next tm 1911s. I now wonder if there's a drawback of doing the mod on the disconnector? (I couldn't think of one ><) Thanks beforehand! |

||

|

|

|

|

|

#928 |

|

I don't see any real drawback. Maybe real long term you might have wear issue since for TM's stock "pot metal" part much of the hardness is from that chrome color plating, and doing this mod will essentially remove that coating partially, and this part in my case is in contact with the much harder steel sear. But the forces we are dealing with is not great and the contact point is small...

|

|

|

|

|

|

|

#929 | |||

|

Quote:

Quote:

) Obviously the shorter it is, the more probable it'll go full auto with zero control, especially with the amount of play in the TM hammer assembly. ) Obviously the shorter it is, the more probable it'll go full auto with zero control, especially with the amount of play in the TM hammer assembly.Quote:

Last edited by StrikeFreedom; March 2nd, 2011 at 15:22.. |

||||

|

|

|

|

|

#930 |

|

I'd pick that(slightly heavier pull) over a dead click TBH....the pull we get are not even in RS range I don't think. Commercial 1911s are like 4-5 lb I think...

|

|

|

|

|

|

|

||||||

| Bookmarks |

|

|

|