Quote:

Originally Posted by e-luder

While this statement is true, I will have to politely disagree...but by a little.A smidgen even  Fair: I am all ears

Fair: I am all ears

THere are many AIRSOFT slides on the market that do not touch the frame at the point you specified and still have a crappy action once mounted.

All too true!!

There are two major causes that I found that is almost present in most Glocks that I've worked on:

1). The bump on the blowback unit- This little bump is the source of the majority of the friction felt by the operator when he/she complains of their action woes.

This bump tends to be too proud and will hit the hammer bearing during normal operation infringing a "smooth" slide action.

This is further exasterbated by the fact that the STOCK recoil spring is not powerful enough to pull the slide to gather enough velocity for the bump to hump over that hammer bearing (i think it's part 50 on the KJW diagram)

As a result, the slide remains open if the case in question is severe.

A perfect example of this is the recent GunsModify Aluminum LightWeight Blowback unit. The ones that I received had the bump so proud that the gun will not travel fluently. In fact, I had to file material away from the hammer housing where the firing pin disconnector is AND the hammer. Crazy!

YES YES YES. i feel you here, and have not so much filed, as i have rounded and polished said hump, to allow a rolling effect over this, causing the cycling to be smoother. I have not seen it as bad as it sounds you have, so egad! more power to you my friend!

2). The other problem is because of the design on the slide rails itself. It's not a continuant guide rail like the P226's front guide rail, which is longer, for example. This causes all kinds of issues once the gun is taken apart for say...cleaning. and put back together.

A perfect example of this is the Guarder Frames. When every nut and bolt is installed, the front rail dips down causing an uneven plain for the slide to glide on. It's stupid really. lol.

At that point, it doesn't matter how much you file the underside of that slide. It WILL hit the frame regardless.

yup, and this contact point can be polished and help smooth the action, that is all i was suggesting.

Because it's a two piece rail system, at some point they will mis-align. Especially if the front screw post breaks and front portion is not bolted to the frame properly.

Ut-Oh.... i have to disagree a smidgen here, in a friendly manner of course...

While this is absolute truth (two rails, tough to align, etc) it is also true that you CAN get them to line up VERY well, and when placing a streight edge on them, make them true. it does take some time, but it is not impossible, and i must admit it is another of the hobby's challenges i like.

Ideally, to eliminate this issue, you want a slide guide rail system that runs in ONE continuous rail. For example, like ILLusion Kinectics' system for the 2011/1911s.

that would be fantastic, yet not possible as i see it. let's make one!!!

Filing the "inner groove" on the slide can cause a potential for a wobbly slide. It's suppose to "hug" those guide rails as close as it can without infringing the action of the slide (that sounds...contradictory. lol.)

ahhhh, thus my "put it in a vice" statement. sounds nuts, but 1mm here and .5mm there can make the "hugging" better, and the polished bits come together nicely. this eliminates said wobble in my practice, not increases it. there are other ways to achieve what we are both writing about, i simply find this fast and easy. let it be said that if anyone tries this it is ALSO EASY TO MESS UP, so be careful you don't squish the slide like a grape, rendering it useless. that would suck! lol

But yes. I still do agree with you though... |

thank you sir, and i you. seems as if we have both enjoyed the Marui G-series a little too much. that does not make us bad!! :P

One last thing i would like to discuss: Graphite lubrication, well, lubrication in general.

there are 3 basic and useful ways to lubricate, some of which i carry over from working on watches. (horology is the trade, to the layman it is "watchmaker") i digress.....

so, lubrication #1: wet. as in, liquid, as in, silicone, 3 in 1 oil, superlube, and a million others i don't feel like typing.

this is the most common, and often highly misused. it is however a simple concept: apply, let sit, wipe clean so nothing comes out during use.

if done right, this can increase life and decrease wear of just about anything from RC Cars to watches, to real steel etc.

Lubrication #2: DRY. as mentioned above, a fine graphite powder is often used to lubricate metals. it is fantastic, yet often misunderstood. this powder was designed (and is still marketed as a key hole lubricant (read: lock cylinder on your car door, home door, etc) and is meant to stay dry after application. its very nature is to have a static electric bond to moving and non moving metal parts of all grades, and therefore should remain in place once the excess has "fallen" off. after working in the industry for 2.5 yrs, this lubrication (the graphite, in case i'm losing anyone by being wordy) has really become popular and is very efficient. i must say that mixing it with an application agent (read: binder) and applying is counter intuitive however. this will cause it to become a paste as mentioned, and that is not its intended use. a polishing rouge would be better suited in this instance IMHO.

Lubrication #3 wax-based: this is perhaps one of my favorites. its quite ingenious actually. originally designed for racing bicycle chains, this is a liquid that is applied, laid to rest, then cleaned off. the liquid leaves the surface (with COLD WATER and MILD hand soap) and what is left is a microscopic layer of WAX. yup, plain old WAX. (commonly used on, say, a Rolex metal bracelet to ensure smooth, squeak free movement of the links. i have used this for a million things, and i find it works wonders on polished, brushed, and bare metal to metal surfaces.) it also lasts a long time, and leaves no byproduct to release during use. they label it as "self cleaning" as well, although i don't see this in execution.

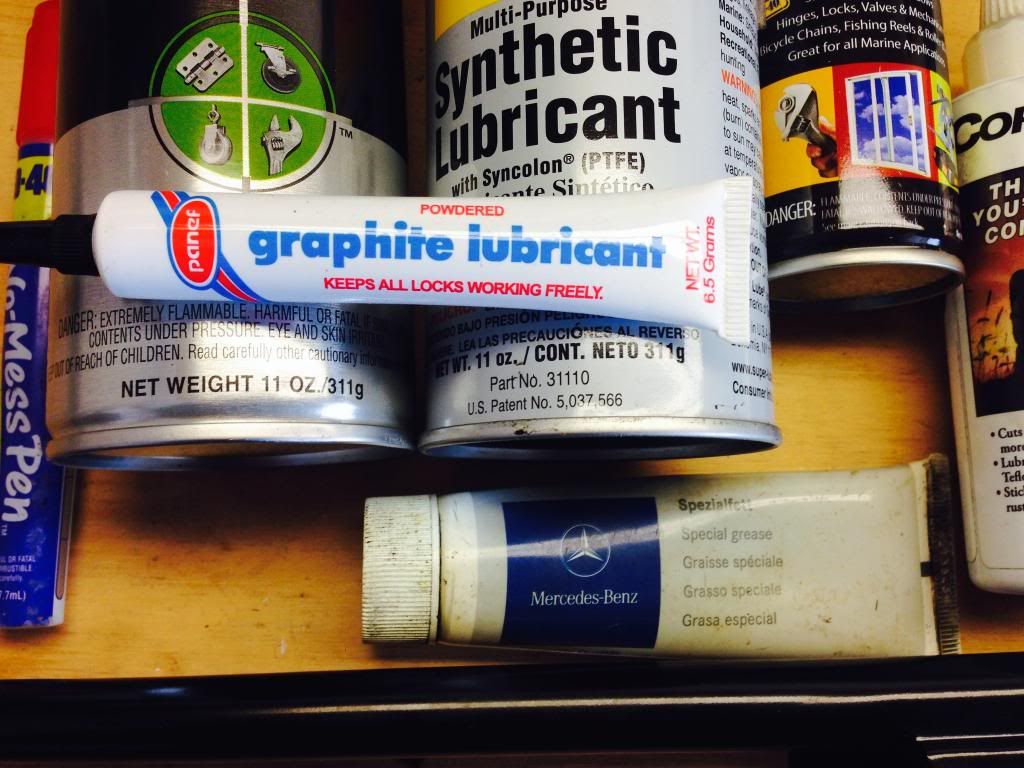

Pictured below are just a few of the ingredients i use, i hope this is helpful to someone.....